New Approaches to the Seaweed Processing Conundrum

Also: Japan issues first kelp restoration carbon credits

In Europe and North America, pioneering seaweed growers have often opted to forward integrate, taking processing and product development into their own hands. That’s either because no other options existed in the absence of a functional market, or because they needed the value added downstream to subsidize unprofitable cultivation.

First step processing comes in 5 flavors: fresh, dried, dewatered, frozen or ensiled (fermented). All have drawbacks, there is no silver bullet, and operators will continue to use a mix of strategies while struggling to figure out a way to do this without burning a hole in their (carbon) budget. Having said that, dewatering and ensiling are currently judged to have an edge.

In the meantime, intermediates are popping up to help growers aggregate supply, work with potential buyers to build up demand and process according to their wishes.

In Maine, The Crop Project had a busy spring, raising $1.5M and processing 200,000 pounds (90 tonnes). In Scotland, Eco-Cascade received grant and prize money to get its processing center up and running by next spring, while Norway’s Algetun has been working for some time on high-capacity freeze drying and innovative heat stimulation. There are also early stirrings of aggregators in Alaska and Sweden.

Biorefining: back to solvents?

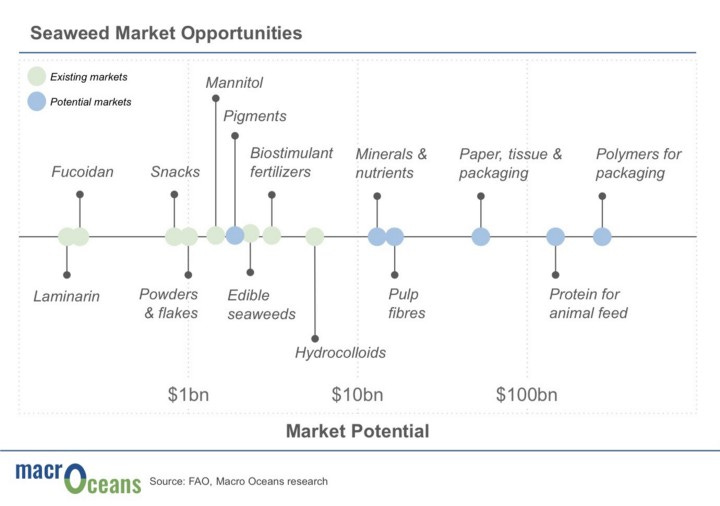

We need to transition to a bio-based economy and we can’t do it without biorefineries. The market opportunity for seaweed as a feedstock for a variety of everyday polymers and chemicals is deep and wide and has attracted a dozen and a half startups so far.

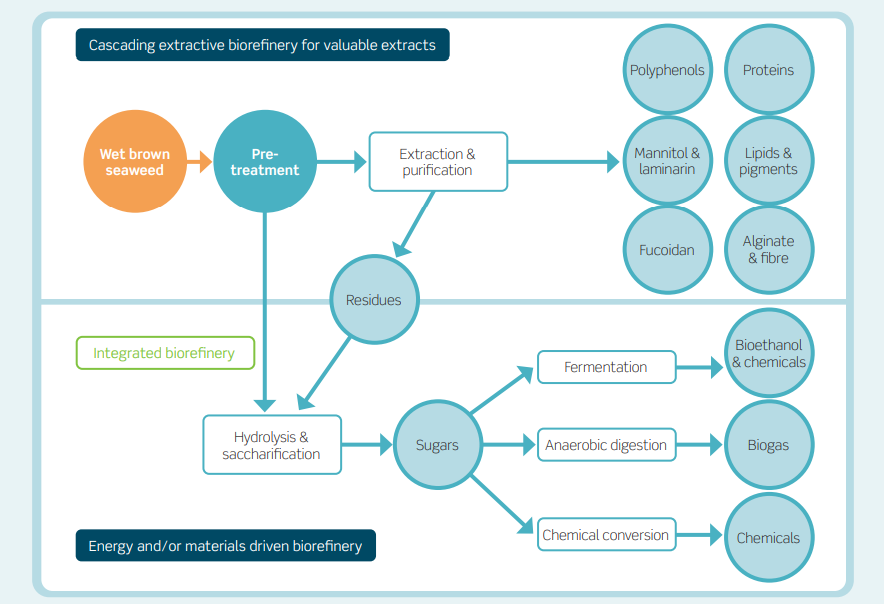

Currently, factories producing alginate, carrageenan, mannitol, … from seaweeds landfill most of the biomass after extraction because they use formaldehyde or other polluting chemicals. New green chemistry allows the use of 100% of the biomass for multiple product streams.

It’s circular, and it allows us to imagine a future where petro-chemicals like acrylic acid ($12B market) or aromatics ($115B) are supplanted by seaweed-based alternatives.

However, these new extraction techniques like ultrasound, microwaves, enzymes, homogenisation and supercritical extraction are still in their infancy and have drawbacks: they are expensive, have low yields, affect the final product and are difficult to scale up.

The SeaSolv project, led by Wageningen University in partnership with Algaia and Kelp Blue, is looking to fix this with a new class of sustainable solvents. Deep eutectic solvents promise a low price, low toxicity, low energy use, customisation and often biodegradability.

Company news: novel biorefinery products

Oceanium has released its first product, Ocean Health Fibre, a replacement for synthetic methylcellulose, often found in plant-based meat replacements. Alt-protein has faced criticism for its long and unnatural ingredient lists; replacing methylcellulose with a natural alternative should be one step in the right direction.

Alginor has ordered a purpose-built kelp harvesting vessel and has secured grant funding for 2 new research projects. As part of the €10 million CIRCALGAE project, Alginor will work on fucoidan derivatives for cosmetics, while the Cellunor project is focused on nanocellulose.

CarbonWave wants to capitalise on early success with its Sargassum-based cosmetic emulsifier by pushing into the Asian beauty market as fast as possible.

Other new entrants are also targeting the cosme-, nutra- and pharmaceutical markets in the first instance. You can already order your fucoidan samples from Nova Scotia’s SeaChange Biochemistry. Moving to pilot-scale soon are This is Seaweed (Ireland) and Macro Oceans (California), while Biomara (Scotland) and Aber Actives (France) have received funding to continue their pre-pilot research.

Japan issues first kelp restoration carbon credits

Urchinomics has secured the world ́s first voluntary blue carbon credit for kelp restoration from their operations in Japan, with backing from oil company ENEOS.

The Japanese Blue Economy Association has validated the science and certified the blue carbon credit, which can now be sold to buyers interested in offsetting their carbon footprint within Japan. The move is sure to fire up the carbon debate once more, as the current scientific majority opinion in Europe and the Americas takes a different view. Megan Howell wrote this summer:

Remediation efforts for macroalgae ecosystems – like culling urchin populations – face notable hurdles for blue carbon financing. Researchers haven’t been able to fully track and measure the amount of carbon sequestered in kelp forests. The impact of climate change on kelp growth is also uncertain, making the long-term viability of projects uncertain. In addition to these theoretical concerns, kelp and seaweed can drift outside the boundaries of offset projects. This makes it nearly impossible to set baselines like permanence and leakage.

Erratum

Last newsletter talked of the world-first discovery of a tropical kelp forest in Galapagos. Javier Infante wrote in to say that it’s certainly not the first time that the genus or kelp in general was described for the tropical region of Galapagos, as Graham et. al already did this in 2007.

Thanks Javier!