Sargassum startups make strides: new harvesters, new products and more funding

Also: investment exits point to further consolidation in hydrocolloids, biostims

Why do alginate producers buy cultivated Sargassum from Indonesia instead of freely available Sargassum from the Caribbean? I wondered about that for a long time. Was it the high arsenic content, the variability in species and chemical composition, the difficulties harvesting it, ...?

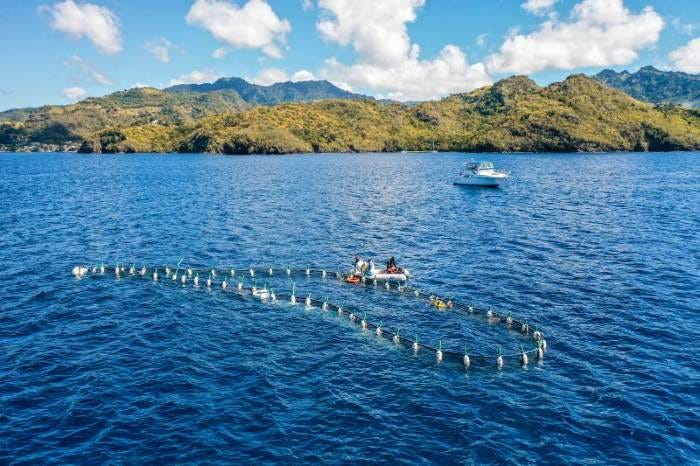

Then Oxenford et al. explained it to me in one image: it’s all of the above, and more.

The challenge of converting wild Sargassum into useful chemicals first hit me when I visited Snap Alginates, which harvests 25,000 tonnes of Sargassum per year from standing seaweed beds in Tamil Nadu, India. Even this experienced processor with a stable, predictable supply has to continuously adjust its processes because the biomass is always changing in composition.

In the Caribbean, as each successive wave becomes bigger than the last, the challenge is so much greater, as the above infographic shows.

A silver lining to this year’s wave is that Sargassum is finally reaching the beaches of Florida, making it a nuisance for some of the richest people on the planet. As a consequence, Sargassum startups have reported a substantial increase in conversations with funders.

With that in mind, let’s have a look at what progress has been made in the past year.

Carbonwave

2 weeks ago, Puerto Rico-based processor Carbonwave announced it raised an initial $5 million Series A round, bringing their total funding so far to $12.9 million, with plans to close on another $2 million within the next month.

The company has seen early success in Korea with its SeaBalance cosmetic emulsifier. They want to move “as fast as possible” in the fast-paced, seaweed-loving K-Beauty market and are now pushing into Europe as well. Regarding its Sarga Ag biostimulant, Carbonwave has stated it solved the arsenic problem and is conducting trials with corporate clients.

According to CEO Geoff Chapin, Carbonwave will collect 45,000 tons in a best-case scenario this year, while the amount processed remains in flux at this early stage of development.

New harvesters

The second generation of Sargassum harvesters is under development. Seaweed Generation has started testing its pilot AlgaRay harvester in Caribbean waters. They are working on a floating charging and docking system which would allow their robots to continue working off-shore. Recent funding from the UK government will go to the development of biodiversity monitoring sensors, cameras and sound recorders to add on to the harvester.

Radical Builders is designing a harvester for Kelp Blue in Namibia, and Goa Ventures is looking to repurpose that experience for Sargassum, it seems.

Thalasso Ocean hopes to have its first 20 ton/hour pilot harvester ready by Q1 2024.

All of these harvesters are designed to be solar-powered, unmanned and autonomous. One road block: autonomous boats are currently not legal in many Caribbean nations. Although the word on the street is that certain governments are willing to change legislation if it can help solve their Sargassum headache, it looks like initially, these boats will be unmanned but often still piloted from the shore.

Seafields

In June last year, C-Cause, a project partnership between Seafields, Carbonwave, The Alfred Wegener Institute and GEOMAR supported by BASF, was awarded €600,000 by the German government to transform Caribbean Sargassum into ethanol, with the aim of producing long-lived engineering plastics.

Seafields also won a £250,000 Innovate UK grant to trial upwelling systems. The company wants to have its first ‘catch and grow’ farms out in the Atlantic by 2024. They plan to reduce the amount of Sargassum that beaches by catching the seaweed further out to sea with barriers, and then turning it into industrial feedstock and carbon credits by processing and/or sinking it.

Seafields has also said it aims to be certified by a standards body at the beginning of 2024 and wants to start supplying carbon credits then. At the time of writing, Seafields is close to hitting the £265,000 target of its crowdfunding campaign.

On a related note: CarbonDrop is a new startup who will soon also feel the wrath of the ocean community as word gets out that they are developing molecular tools to engineer Sargassum for carbon sequestration. The fact that scientific advisor Arthur Grossman was the Chief of Genetics at high-profile microalgae bankruptcy Solazyme (now part of Corbion) will likely only add fuel to the fire.

Processing & product development

Baling

Baling prevents crops from degrading and makes it easy to store and transport them. It’s a necessary component of today’s agricultural supply chains. So, is Sargassum baleable? Yes, it is, and it bales well.

Origin by Ocean and their partners SOS Carbon proved it last October, making a big step forward towards an industrial-scale Sargassum supply chain. The company is piloting its refinery in Finland. In a later stage, it wants to set up a processing plant in the Dominican Republic.

Containerised micro-biorefineries

Thalasso Ocean, with the support of the Norwegian government, has made a digital twin of its micro-biorefinery concept, built to fit into two shipping containers. The first instance is set up for the production of alginate, fucoidans and biostimulant.

Interest in Thalasso’s micro-biorefinery idea has spread from the Caribbean to other parts of the world like Norway, Canada and Alaska, places where a small, easy-to-move processing setup could be a great fit for remote landing sites and short harvesting seasons. The company is currently raising a seed round to get their solution from the digital realm into reality.

Shoe soles, biostimulant & biogas

Bloom, who make rubbers and plastics from microalgae blooms, is now also making shoe soles from Sargassum, it seems. That gives us a chance to highlight the work of Mexican pioneers Renovare, who have been producing shoes from Sargassum and recycled plastic bottles for a decade.

Algas Organics figured out how to make biostimulant from Sargassum 9 years ago. Hailing from St. Lucia, it’s been a long slog to get access to funding and sizeable markets, but now it is happening. With private equity dollars and a foot in the door with large-scale cannabis growers, Algas feels ready to scale up far beyond its current 500 tonnes of Sargassum per year.

Last but not least, Rum and Sargassum, the startup looking to power Barbados with biogas from Sargassum, rum distillery wastewater and sheep manure, is moving to pilot scale.

Investment exits point to further consolidation

Leading hydrocolloid manufacturer JRS has acquired Algaia. Following the acquisition of DuPont’s former alginates business with production site in Landerneau, Brittany, in 2018, this union will make JRS one of the three largest alginate producers outside China, the other two being Kimica with production in Japan and Chile, and IFF with production in Norway.

Mitsui bought a stake in Irish biostimulant company C-Bio, thereby becoming the latest in a growing line of multinationals to invest in seaweed biostimulants.

Ocean Harvest Technology went public and raised £6 million. In the process, they gave us a tantalizing glimpse of the size of the seaweed for animal feed market: OHT delivered product revenue of €2.5 million in 2022, a 67% increase on the prior year. At the current stock price of ~17p, the company is valued around £22 million.

And finally, Australian startup Southern Ocean Carbon Company, which is trialing seaweed aquaculture in Tasmania, was acquired by ADEC to “further expand its ESG expertise into the blue economy.”