Alaskan mariculture gets $49M grant, registers 27% growth

Also: how to get costs down for seaweed cultivation and nurseries?

The Alaska Mariculture Cluster won a $49 million US federal grant this September to boost shellfish and seaweed aquaculture in Alaska.

“The past two governors have had a working group, the mariculture task force, that provided a really good framework and blueprint for how this industry could grow to be a $100 million industry in the next 20 years at the pace it was going. An opportunity like this allows us to hit the fast forward button and do that in much less time.”

Complementing the grant are a new strategic research plan and an assessment of seaweed processing locations in Alaska published earlier this year.

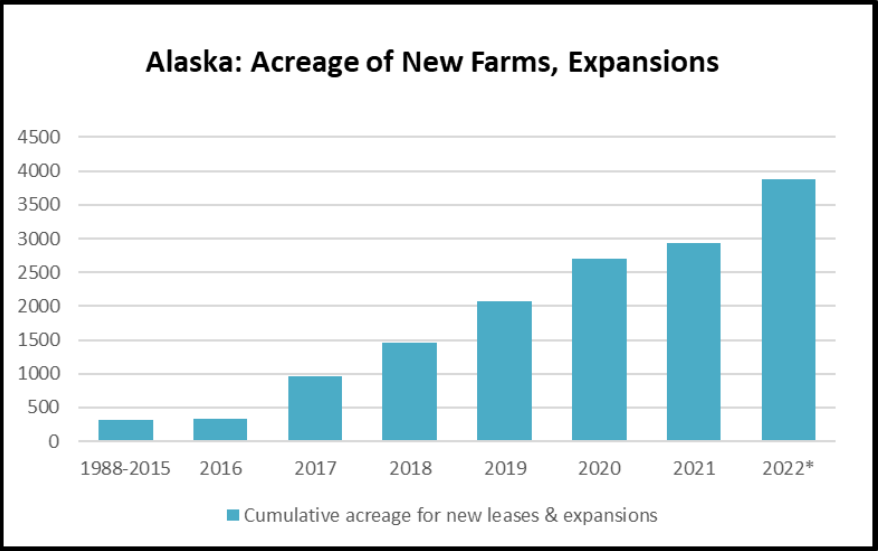

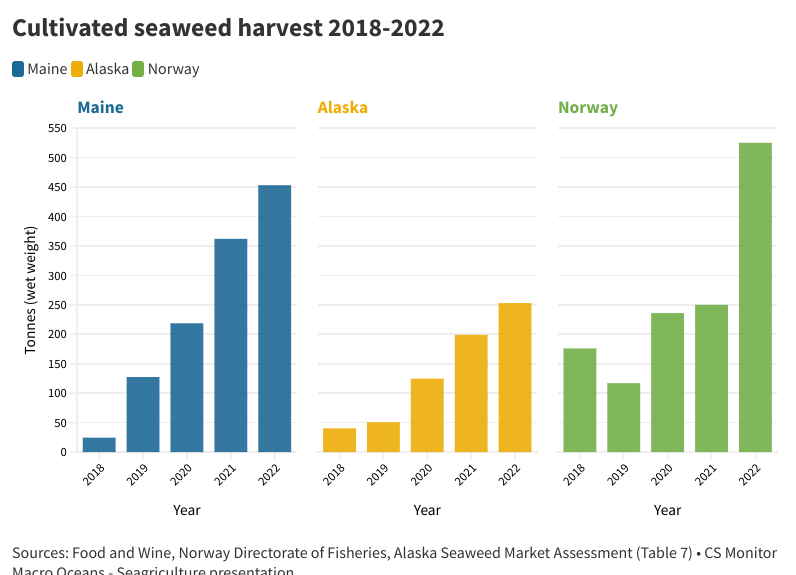

The Alaska mariculture cluster projects a 58 million pounds (26 000 tonnes) harvest by 2030. In 2022, growers in Alaska harvested a reported 556,750 wet lbs (253 wet metric tons), up ~27% from 2021.

Currently there are only 8 active farms out of 24 fully permitted ones, with an additional 23 licenses under review. That means we’re likely to see a further rapid increase in Alaska production.

For instance, The Native Conservancy, an Indigenous-led land conservancy, is aiming to foster 100 Native-owned kelp farms over 2,000 acres (800 hectares) of ocean within 10 years.

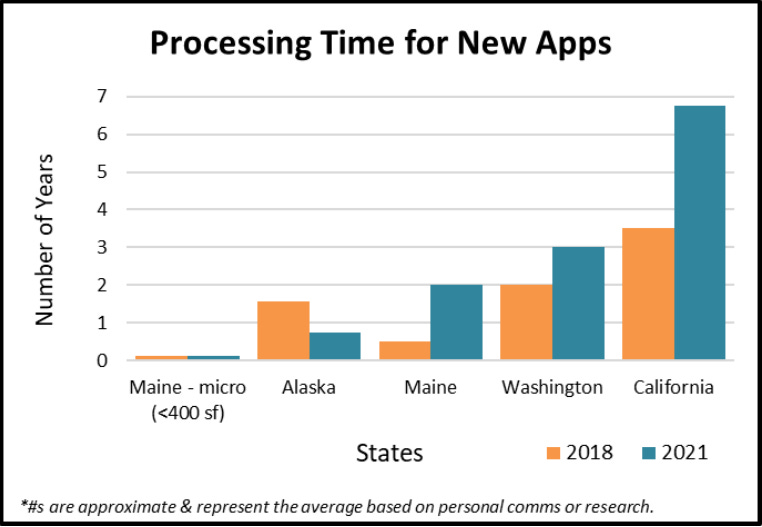

What really sets Alaska apart from the rest of the US is the political buy-in at the state level. Besides grants for research and industry and the setup of the Alaska Mariculture task force, this is most obvious in the time it takes to get a license for a seaweed farm approved in Alaska.

Sugar, winged, or bull kelp?

82% of Alaska’s 2022 harvest was sugar kelp, 18% winged kelp. Most of this year’s harvest was frozen before being sold to food companies for further processing, with a noticeable uptick in volumes going to animal feed (reportedly ~80,000 lbs) and biostimulants.

However, According to Dr. Tiff Stephens, wild harvested bull kelp is Alaska’s most successful kelp for commercial sales. That business could disappear soon, as conservationists are seeking endangered species protection for bull kelp. While protection sounds like good news, since it would protect the remaining bull kelp from trawling for the alginate business, it could also turn out to be counterproductive, as the inclusion in the endangered species act will likely restrict bull kelp aquaculture and restoration projects.

Comparing to Maine and Norway

Drawing together newly published numbers from Maine and Norway’s cultivated seaweed harvest, here is how Alaska compares.

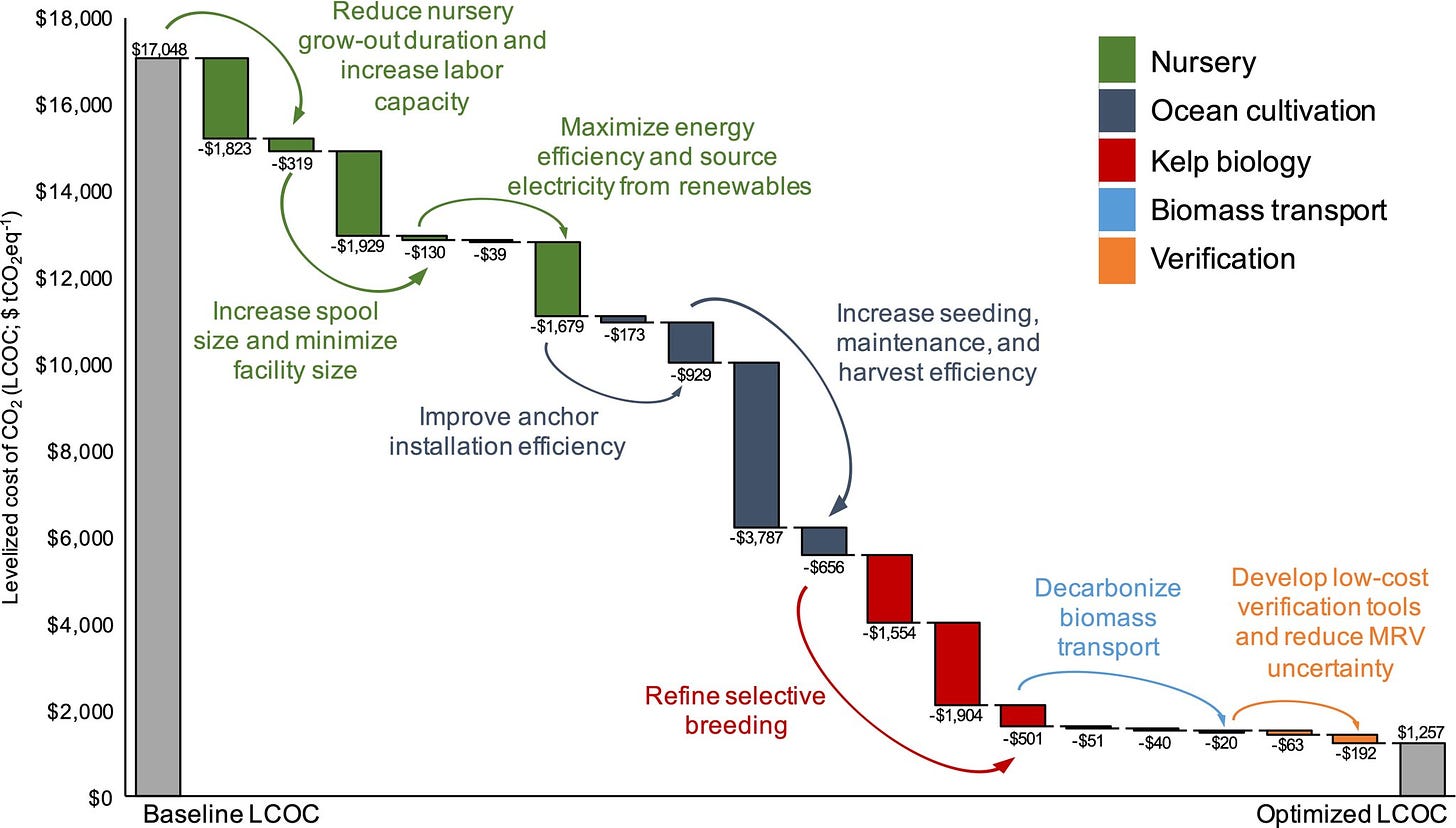

How to get costs down?

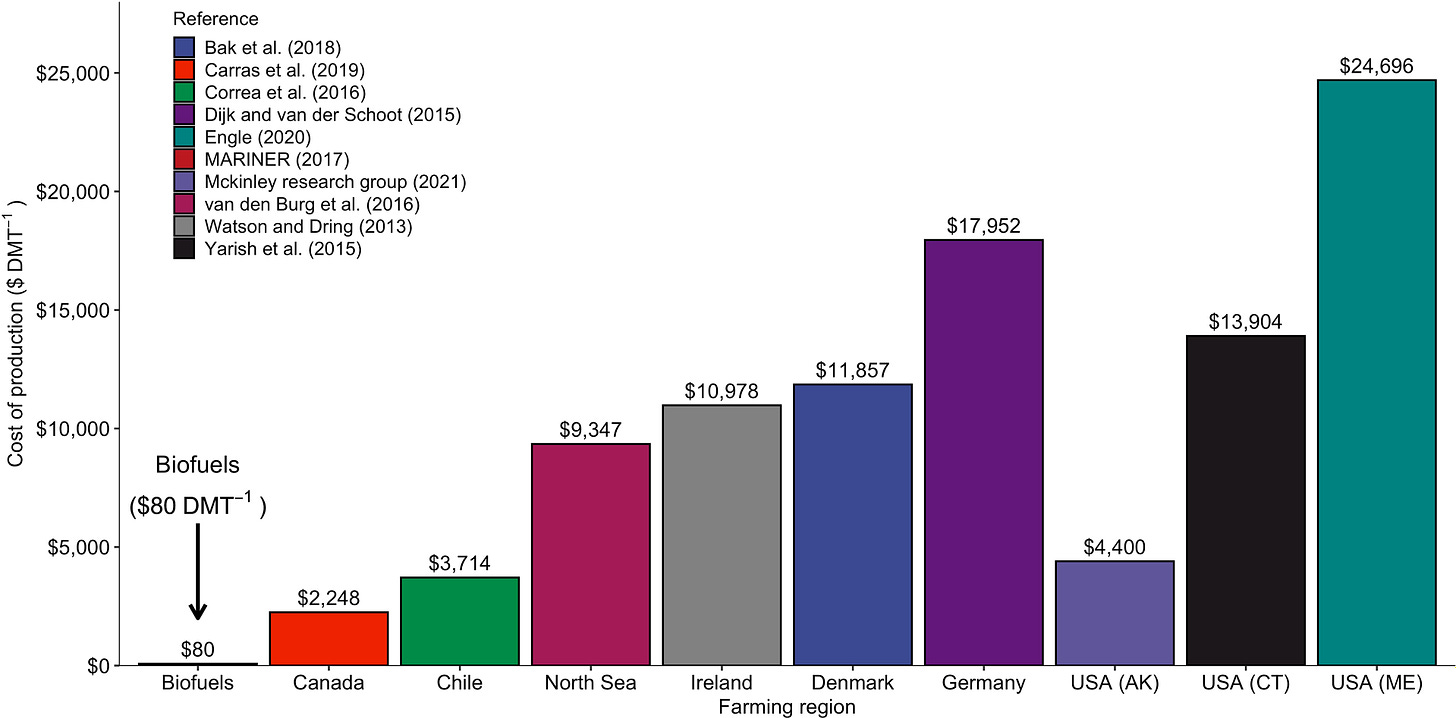

Seaweed cultivation in Europe and North America is expensive.

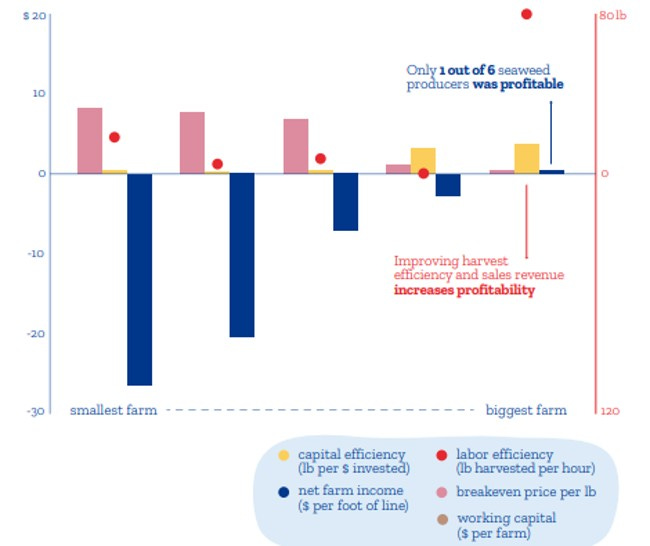

Should seaweed cultivation be done in large-scale farms or by cooperatives of small-scale producers? Like with other forms of food production, this is a debate that will not see a resolution any time soon. But in terms of profitability, at current technology, the larger the farm, the more profitable.

Labor is the biggest cost in the North American seaweed industry. Another recent study modeled a 22% decrease in the production cost of North American kelp by optimizing harvesting efficiency.

If you are running a nursery, once again, scale is going to have the biggest impact on your bottom line. Reducing the duration of grow-out is another critical research priority to reduce costs in future.

One more innovation to get costs down: researchers at the Woods Hole Oceanographic Institution have developed an automated underwater seaweed seed-string deployment device that eliminates the need for grow-line attachment and detachment which will allow farmers to seed much faster than traditional methods. The method substantially lessens the time the seed spool spends in the air, reducing the time of exposure to the elements from minutes to seconds to increase seedling survivability. Removing the above-surface component from seeding will also increase the weather window in which seeding can occur.

Automation finds success in India

Finally, automation is also what Sea6 Energy have been working on for the past 10 years in India and Bali, building a seaweed harvesting tractor and automatic planting machine, among other things. Their recent $18.5 million Series B from Aqua-Spark and BASF shows that investors see promise in the automation of tropical algoculture.

Always happy to see Phyconomy in my inbox! Thanks Steven.

This was a great one, Steven! Super informative on the true modern costs of the industry.